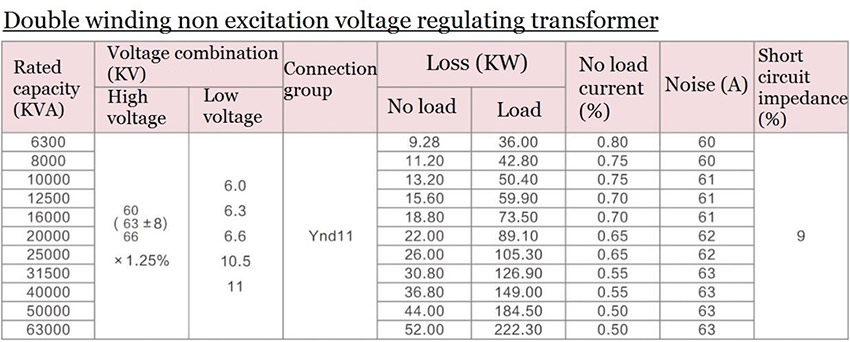

The SZ, SFZ, SFS, and SFSZ series power transformers produced by our company have a maximum capacity of 240,000kVA for a 110kV voltage class and 400,000kVA for a 220kV voltage class. This series of products are power equipment with low loss, low noise, low partial discharge, and strong short-circuit resistance, independently developed by combining domestic and foreign advanced technologies. The transformer can transform the grid voltage into the voltage required by the system or load, and realize the transmission and distribution of electric energy. This series of products can be installed and used outdoors (or indoors), and are especially suitable for operation in humid environments. They are ideal power distribution equipment in factories, rural and urban vast power transmission and distribution networks.

Product features:

1. The iron core is made of cold-rolled grain-oriented silicon steel sheet, with 45° full oblique joints, no middle hole and epoxy tape binding structure, and the iron core surface is coated with iron core protective paint to reduce loss and noise;

2 .Using a new type of oil channel structure, high heat dissipation efficiency, reducing the temperature rise of the transformer and prolonging the service life of the transformer;

3. The box adopts a fully sealed structure of the corrugated oil tank to prevent air and water from contacting the transformer oil, reducing the aging degree of the oil. The service life of the transformer is extended, and the volume change of the transformer oil in thermal expansion and contraction is adjusted through the elastic deformation of the corrugated sheet;

4. The transformer is equipped with pressure release safety protection. When the transformer fails and the pressure is too high, it can be reliably and safely through the pressure release valve release to prevent the expansion of the accident.

Product advantages:

1. Strong short-circuit resistance. Advanced calculation programs are used to calculate the short-circuit condition of the transformer, and analyze the force and deformation of each part of the coil under the short-circuit condition. It can greatly improve the anti-short circuit capability of the transformer.

2. Low-loss optimized electromagnetic calculation, using multiple shielding methods to control magnetic flux leakage, reduce load loss and avoid local overheating. Cold-rolled lattice-oriented high-permeability silicon steel sheets are selected, fully inclined STEP stepping joints are adopted, and no holes and no iron yokes are stacked to reduce no-load loss, no-load current, and electromagnetic noise.

3. The body of high mechanical strength adopts the six-sided positioning method, which can meet the transportation acceleration of not more than 0.3g in the horizontal direction and not more than 0.15g in the vertical direction.