Power Transformer

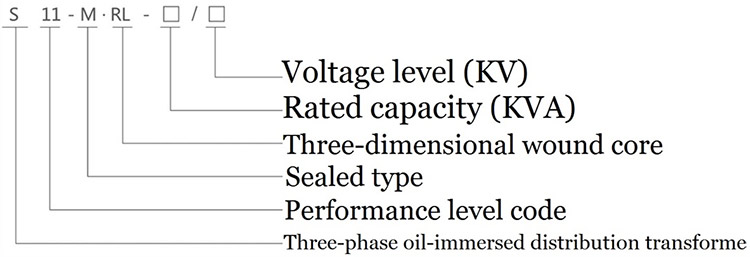

S13-M.RL Three phase oil immersible power transformer transformer

- Product ID:Power Transformer

- Whatsapp & Wechat:+8613868719385

- Phone: +8613868719385

- Tel: +86 577 27880251

- E-mail: info@dlxex.com

- FEEDBACK

S11/S13—M. RL series 10kV grade solid core transformer is a newly developed product, which breaks through the traditional planar structure and adopts three-phase symmetrical solid structure. And because there is no air gap in the magnetic circuit, the winding is more compact, the magnetic conduction direction of the silicon steel strip is completely consistent, the three core columns are arranged in an equilateral triangle solid, the three magnetic circuits are the same length, and all are the shortest, and the processing and nesting are free of materials; Therefore, it is an efficient and energy-saving transformer that uses traditional materials, but has lower operating noise and more compact structure. Its outstanding performance in reducing loss and saving materials fully conforms to China’s energy conservation policy, and is widely used in high-rise buildings, commercial centers, airports, tunnels, chemical plants, nuclear power plants, ships and other important or special environmental sites. This product meets the requirements of the national standards: General Rules for Power Transformers (GB1094.1-1996), Power Transformer Temperature Rise (GB1094.2-1996), Power Transformer Insulation Level and Insulation Test (GB1094.3-2003) and Power Transformer Short Circuit withstand Capacity (GB1094.5-2008).

Categories

LATEST NEWS

CONTACT US

Whatsapp & Wechat: +8613868719385

Phone: +8613868719385

Tel: +86 577 27880251

E-mail: info@dlxex.com

Add: 86# sanliyi road, Wenzhou, Zhejiang China